The department distinguishes itself with a strong focus on experimental research. Students who have this basic understanding can now implement this knowledge to develop a more profitable result.The Ken and Mary Alice Lindquist Department of Nuclear Engineering at Penn State is one of the top ranked nuclear engineering programs in the United States.

#Leonhard building penn state manual#

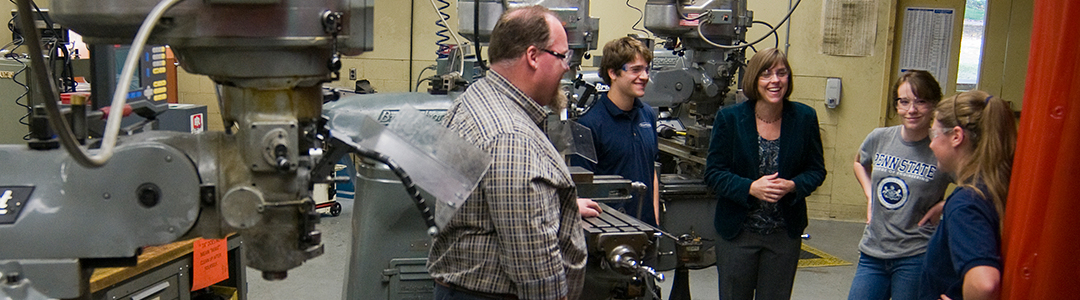

The manual machining exposure our students receive from this area provides them an opportunity to better understand basic machining principles, methods, and procedures. This area is also used to fabricate the fixtures and tooling required to support unique research projects. During several weeks of lab activities, student groups collect critical machining data while performing tool-cutting force experiments, tool-wear experiments, and orthogonal cutting force experiments. The manual machining area of the lab is used for conducting various machine tool-cutting experiments by undergraduate and graduate students. Lincoln Electric Semi-automatic SAW Welder.

The laboratory has six welding booths equipped with: The main objectives of the laboratory experiments are to reinforce the principles and theoretical concepts taught in the classroom and to introduce students to the equipment, procedures, and difficulties associated with the welding process. This area of the FAME lab provides students with instructional experience on conventional and non-conventional welding processes. The metal casting lab also includes sand testing equipment, a pattern-making facility, and metallograph and carbon sulphur analysis instrumentation. Students gain valuable hands-on experience by undertaking the molding and casting themselves under the direction of a skilled technician and teaching assistant. A wide variety of casting and molding processes are used including green san casting, resin-bonded sand casting, the evaporative casting process, and permanent mold casting. The laboratory uses a medium frequency coreless induction furnace for student instruction and experimentation with both ferrous and non-ferrous metals.

#Leonhard building penn state software#

The metalcasting area of the lab provides students with instructional experiences in metalcasting and the use of software tools for gating, risering, and solidification modeling. The availability of these machines for undergraduate and graduate education has led to significant revision to the manufacturing courses and curriculum, and gives the students real life experience with machines used in industry.

The center provides students with state-of-the-art CNC machines for education and research and is equipped with: The center is the result of a unique alliance between Penn State, HAAS Automation, Inc., and the HAAS Factory Outlet, a Division of DSM Machinery. The HAAS Technical Education Center was established in June 2000, through the generous support of HAAS Automation Inc. In addition, the lab includes automated high-tech facilities dealing with robotics and assembly featuring computer-integrated manufacturing cells and robots.įAME is comprised of several specialized areas including: HAAS Technical Education Center It houses many diverse manufacturing processes including casting, welding, machining, forming, injection molding, and assembly systems. The lab has most of the elements of a real manufacturing facility. The main objectives of FAME are to reinforce the principles and theoretical concepts taught in the classroom and to introduce students to the equipment, procedures, and difficulties associated with common engineering processes. It is a 10,000-square foot-integrated high bay laboratory for teaching and research. The Factory for Advanced Manufacturing Education (FAME) Lab is located in Room 106, the heart of the Leonard Building. Factory for Advanced Manufacturing Education Lab

0 kommentar(er)

0 kommentar(er)